Jun 4 2020

The design of bridge decks for suspensions bridges have not undergone any fundamental change in the last six decades. These bridges are well known from the Great Belt Link in Denmark.

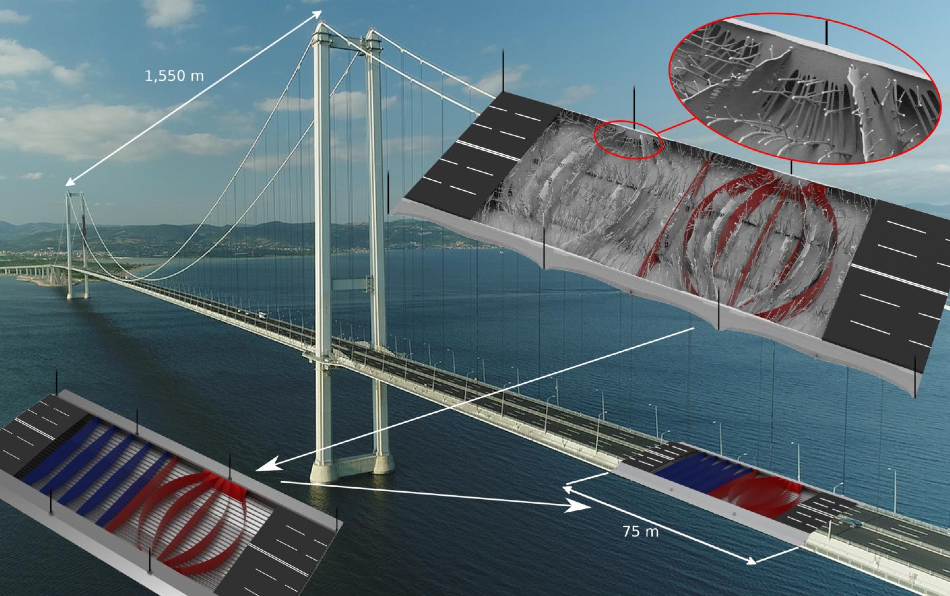

The Turkish Osman Gazi suspension bridge is visible in the background and the topology optimization result in the top right. Subsequently, the result of the optimization—organic in appearance and highly complex—was interpreted, which led to a new, simpler design (marked in red). Compared to the conventional design (marked in blue), the new design entails weight savings of more than 28% for the bridge girder. The white arrows indicate the course of the design process. Image Credit: Technical University of Denmark.

The Turkish Osman Gazi suspension bridge is visible in the background and the topology optimization result in the top right. Subsequently, the result of the optimization—organic in appearance and highly complex—was interpreted, which led to a new, simpler design (marked in red). Compared to the conventional design (marked in blue), the new design entails weight savings of more than 28% for the bridge girder. The white arrows indicate the course of the design process. Image Credit: Technical University of Denmark.

To fulfill the demand for ever longer bridges, the Technical University of Denmark (DTU) and COWI analyzed ways to optimize structures to bring down the bridge deck weight, specifically increasing the span. The study results were published recently in the renowned scientific magazine Nature Communications and suggest immense potential.

We applied different methods for examining how to better utilise materials, which primarily consist of steel and concrete. Initially, we sought to optimise their use in traditional structures by using transverse diaphragms in the bridge deck, thereby achieving a theoretical weight reduction of up to 14 percent.

Mads Jacob Baandrup, Engineer, Bridges Department, COWI

Baandrup performed the analyses in relation to his PhD project.

New Curved Design Makes the Difference

To achieve further savings, the team investigated the possibility of modifying the structural design. This was performed through topology optimization, a technique used in aircraft and car industries, that had not been used earlier for large-scale building structures.

In popular terms, it’s about ‘emptying’ a bridge girder of its existing elements, providing complete freedom for choosing a new design. The inner volume of the bridge girder is then divided into a structure of very small voxels (3D pixels), like small dice.

Niels Aage, Associate Professor, Department of Mechanical Engineering, Technical University of Denmark

Aage, one of the world’s leading researchers in large-scale optimization who contributed to the project analyses, added, “The topology optimisation method is then used for determining whether each individual voxel should consist of air or steel material. The result is a bridge girder design that uses the least possible steel without impairing the strength of the structure.”

Particularly, a bridge element that measures 30 x 5 x 75 m was analyzed by splitting it into two billion voxels, each not measuring more than a few centimeters. The outcome was a remarkably extensive calculation carried out by a supercomputer, which would have taken 155 years for an ordinary computer to do and is the largest-ever structural optimization.

Carbon Saving and Economically Interesting Solution

Through the computer calculation, the researchers obtained input for the best ways to structure the design space of the bridge deck. That specifically implied curving a portion of the currently straight transverse diaphragms, thus enabling 28% of the material used for bridge decks to be shaved off. This thus helps realize a corresponding reduction of the CO2 emissions produced by the manufacture and transport of steel and concrete.

“We interpreted and adjusted calculations so the result became a suggested bridge girder structure with the optimum design that can be carried out without too costly production methods. The economic aspect is important in order for the design to be a realistic option for future bridge projects,” added Mads Jacob Baandrup.

Valuable Knowledge for Tomorrow’s Suspension Bridges

Most certainly, further analyses will be needed before using the new design to build bridges. However, COWI believes that the results of the study offer valuable insights into futuristic suspension bridges.

The new bridge girder design can be converted into a weight and CO2 reduction of up to 20 percent for the entire bridge, which of course benefits the climate. COWI is also involved in a wide range of the world’s largest bridge projects, so a potential new design will also benefit our customers and society.

Henrik Polk, Technical Director, COWI

DTU is also very excited about the study outcomes.

According to Professor Ole Sigmund from DTU Mechanical Engineering, “We believe there are huge perspectives to using topology optimisation for ensuring the sustainable design of other large building structures, such as high-rises, stadiums or highway bridges. We want to explore that field, and since the construction industry accounts for 39 per cent of global CO2 emissions, almost any reduction can be of interest.”

A PRACE (Partnership for Advanced Computing in Europe) supercomputer was used to perform the calculations for the topology optimization.

Journal Reference:

Baandrup, M., et al. (2020) Closing the gap towards super-long suspension bridges using computational morphogenesis. Nature Communications. doi.org/10.1038/s41467-020-16599-6.

Source: https://www.dtu.dk/english