If you’re looking to kickstart a career in concrete grinding and polishing or elevate your business to a new level, choosing the right concrete grinder is crucial.

Proper equipment should remove coatings, grind, hone, or polish a concrete surface. Onfloor has lots of high-performance equipment to help achieve the surface profile your client has requested, but with minimal mess and effort.

One of the best pieces of equipment for getting a concrete floor into shape is a concrete grinder. In light of that, this article is taking a deep dive into what you can use a concrete grinder for and our featured piece of machinery, OF20S-H.

More specifically, why OF20S-H is the perfect fit to elevate or start your concrete grinding and polishing business.

We have lots to cover, so let’s get started.

What Is The Purpose Of A Concrete Grinder?

As concrete is a natural element, it degrades with time. To maintain the concrete floor's appearance and functionality, it needs reviving from time to time.

A concrete grinder is a piece of equipment used to create a smooth finish on a concrete surface.

Essentially, a concrete grinder is like sandpaper to wood. It will leave a more polished, smoother finish to the concrete and help eliminate dirt, harmful industrial concrete elements, and grease.

Selecting A Concrete Grinder That’s Right For You

Before choosing a concrete grinder, you first need to know what it is you want it for. What jobs will it be used on- small, compact spaces? Large, open space? On wet or dry concrete?

Concrete can be polished using both a wet and dry method, but usually, a combination of the two is used:

1. Wet Grinding- Using Water:

This helps to get rid of the dust and dirt on concrete and makes the diamond abrasives cooler. Water intervenes as a lubricant that helps to extend the life of the abrasive tools on your concrete grinder.

For example, water can help prevent resin-bonded discs from melting due to high temperatures. The downside to wet grinding is that it can be a bit messy, and the cleanup process is another job in itself.

2. Dry Grinding- Water-Free:

This step is done at the beginning of a concrete grinding job as it removed the bulk of the concrete. When the concrete is smooth, it is then recommended to switch to wet grinding.

Top Tip: When switching from dry to wet, change the metal bonded diamonds for the resin-bonded abrasives. These resin-bonded abrasives don’t require water, so they can also be used for dry polishing.

Types of Concrete Grinders

There isn’t a standard concrete grinder that covers every grinding job. Each grinder is explicitly designed for a different job. So it’s essential you know what type of job you want the equipment for so you can use the proper machinery.

Single and Dual Disc Grinders

If you’re a commercial concrete grinder, a single-disc concrete grinder probably isn’t suitable for your needs.

Single-disc concrete grinders are perfect minor residential concrete jobs. They are lightweight and plugged into a regular wall outlet as they operate at 110 volts and 15amps.

These grinders are very narrow, so they're suitable for these small, residential jobs. If your grinding job is less than 1,000 square feet, then this single-disc grinder could be the perfect fit.

As the name suggests, dual-disc grinders include two discs. These discs spin separately and are great for industrial and commercial grade grinder jobs. They can cover much more concrete than the single-disc and are wider.

If your grinding job is more than 1,500 square feet, then a dual-disc grinder is more suited to your professional needs. They are best for outdoor use, are powered by either gas or propane, and roughly use 110 volts and 20 amps.

Planetary Grinders and Rotary Floor Grinders

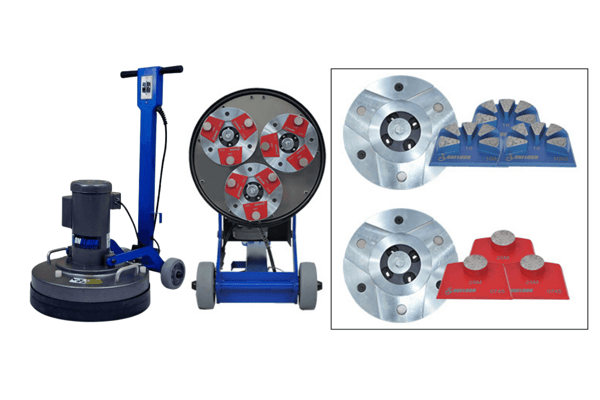

Planetary grinders are usually made up of three discs that each spin separately around a central point. These grinders are ideally suited for large grinding projects and are mainly used as floor polishing equipment.

Compared to a rotary grinder, planetary floor grinders are usually lighter, easier to use, and more maneuverable. Rotary floor grinders, on the other hand, are much bulkier and heavier.

Rotary grinders can remove multiple layers at faster square meter rates due to their weight and size. However, the downside is that they demand a high-skilled operator to perform optimally, whereas a planetary grinder doesn’t.

Multi-Surface Grinders

Multi-surface grinders can quickly grind both hard and soft surfaces, such as concrete, stone, and wood. This is because multiple tools can be placed on the grinding heads.

As Onfloor is known for its quick-change patented tooling, this is an effortless and quick process.

The OF20S-H

After reading all the above, it may seem like there are too many things to consider and options to choose from. However, the OF20S-H could be the piece of equipment that is perfectly suited to your needs.

If you’re looking to launch a business in the concrete grinding and polishing industry or want to elevate your business with a multi-purpose piece of equipment, look no further than Onfloor’s OF20S-H.

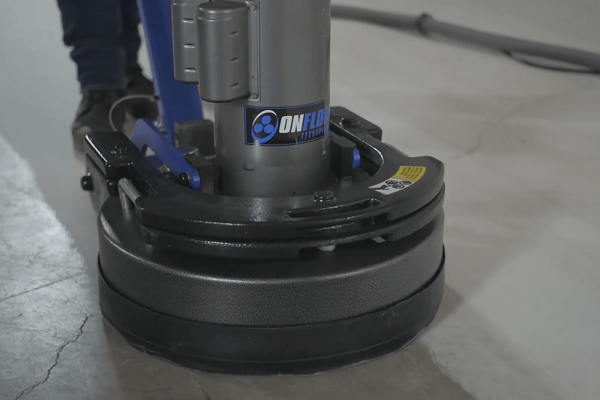

The OF20S-H is a multi-surface, Planetary, 20” single high-speed grinder and polisher. If that’s not enough to win you over, keep reading as we delve into what this piece of machinery can do.

With Onfloor’s patented triple-belt planetary tech, the OF20S-H can help you complete your work faster than any other.

Operating at 208-240V, 1 phase, this machine is powerful enough to be used professionally but easy enough to for almost anyone to maintain and operate.

The OF20S-H operates at a high speed of 1000 rpm (rotations per minute), boasting production rates as impressive as 500 square feet per hour.

Adding to this, the machinery includes Onfloor’s patented tool attachment system, known for being the fastest tool change in the industry.

Tooling packages are available for many applications, including:

- Mastic/Glue removal

- Concrete Surface Preparation

- Epoxy Removal

Let's quickly condense the key points:

The OF20S-H Summed Up:

That's a lot of info, so let's sum this up:

- High-Speed Grinding on multiple surfaces: Grind Concrete, Terrazzo, Stone, and more.

- 20” Cutting Path: cover more area in less time

- Lightweight: This allows for the high speed to really be utilized and offers greater mobility.

- Removal handle: this reduces the overall height for increased mobilization

- Up to 282 lbs Grinding pressure: More grinding pressure increases productivity.

- Patented Flexible Tool Plates: Follow the contour of the floor to achieve faster production

- Patented Triple Belt Planetary: Create more torque with less power.

- Wet/Dry Operation: This machine can operate dry with a dust collector or wet with water—no need for two separate devices.

It's also a self-maintenance platform - which means you can replace the belts and bearings in minutes, not hours.

The Leading Commerical Concrete Floor Grinder: OF20S-H

There are many reasons why the OF20S-H is the leading commercial concrete floor grinder.

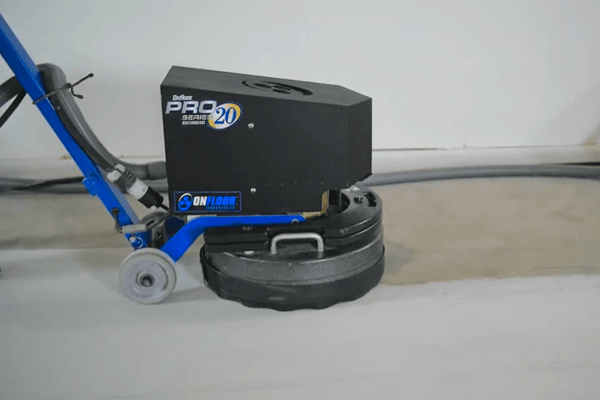

The machine is perfectly designed for commercial use: lightweight for better mobility while durable and capable of achieving high-speeds and fast production rates.

This concrete grinder has planetary disc grinders that make large-scale jobs easier and function as a concrete polisher.

Overall, the OF20S-H is a high-performance, high-achievement machine, with little restriction on who can use and maintain it.

For more information about this, please feel free to contact us today!

3 comments