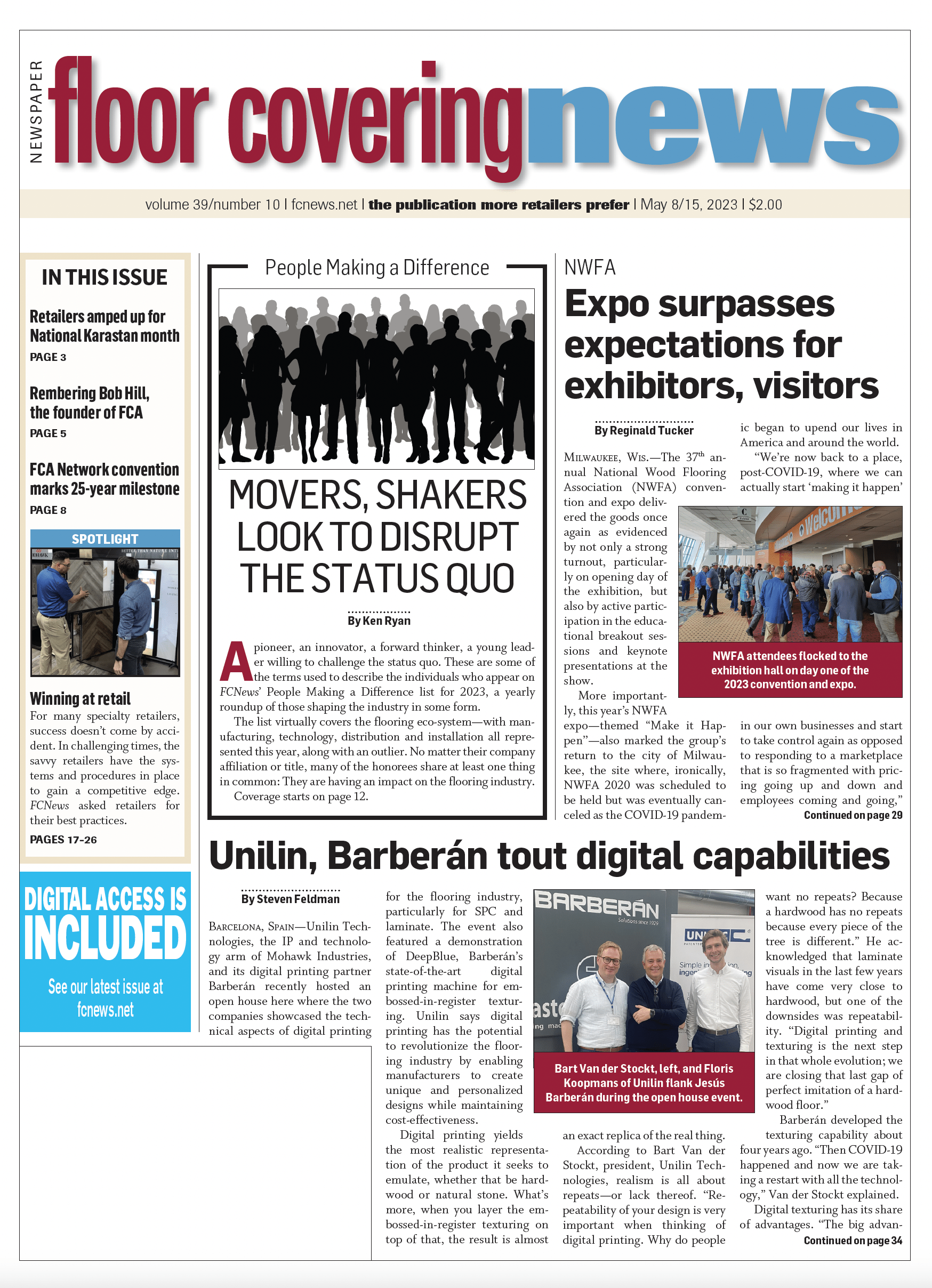

Barcelona, Spain— Unilin Technologies, the IP and technology arm of Mohawk Industries, and its digital printing partner Barberán recently hosted an open house here where the two companies showcased the technical aspects of digital printing for the flooring industry, particularly for SPC and laminate. The event also featured a demonstration of DeepBlue, Barberán’s state-of-the-art digital printing machine for embossed-in-register texturing. Unilin says digital printing has the potential to revolutionize the flooring industry by enabling manufacturers to create unique and personalized designs while maintaining cost-effectiveness.

Digital printing yields the most realistic representation of the product it seeks to emulate, whether that be hardwood or natural stone. What’s more, when you layer the embossed-in-register texturing on top of that, the result is almost an exact replica of the real thing.

According to Bart Van der Stockt, president, Unilin Technologies, realism is all about repeats—or lack thereof. “Repeatability of your design is very important when thinking of digital printing. Why do people want no repeats? Because a hardwood has no repeats because every piece of the tree is different.” He acknowledged that laminate visuals in the last few years have come very close to hardwood, but one of the downsides was repeatability. “Digital printing and texturing is the next step in that whole evolution; we are closing that last gap of perfect imitation of a hardwood floor.”

Barberán developed the texturing capability about four years ago. “Then COVID-19 happened and now we are taking a restart with all the technology,” Van der Stockt explained.

Digital texturing has its share of advantages. “The big advantage of digital printing is you can change your décor on the fly, but if your texturing cannot follow, you don’t have that huge advantage,” said Floris Koopmans, sales director, Unilin. “So both your décor and texture need to be flexible and adaptive, and they need to communicate with each other so you have that perfect embossed in register.”

Digital texturing has its share of advantages. “The big advantage of digital printing is you can change your décor on the fly, but if your texturing cannot follow, you don’t have that huge advantage,” said Floris Koopmans, sales director, Unilin. “So both your décor and texture need to be flexible and adaptive, and they need to communicate with each other so you have that perfect embossed in register.”

Two other advantages are speed and cost. “Manufacturers do not have to buy the big embossing rolls anymore,” Koopmans explained. “If they want to change the texture, they can do it with just a touch of a button.”

The final advantage centers around China—and it goes much further than logistics. “People think of the print and wear films they need to import from Asia, and they know logistically it would be easier if you could print them yourself,” Van der Stockt said. “But it’s also about design freedom and creativity. When printing digitally they can keep the designs in-house and bring them to market instead of using external parties, which increases the risk of copying of the design.”

Unilin’s Van der Stockt reinforced that innovation is important, but innovation must be executed and it must solve a problem. “If you look at what has been the biggest innovation of the last decade, I think it’s safe to say it’s the LVT/SPC wave of the past decade. Why? Because it solved issues that existed at that time related to water resistance and sound with laminate, and it solved the installation problem of ceramic. When is an innovation successful? When it solves problems. Why do I believe digital printing can be successful? Because it’s solving problems.”

Following the path of ceramic

Koopmans compared the opportunity that exists today with digitally printed SPC to the ceramic industry 20 years ago, when digital printing didn’t even exist. However, over time, everything moved to digital. “Before, ceramic manufacturers had huge complexity and were limited in design capabilities,” he said. “Manufacturing was very time consuming, labor intensive and there was a lot of waste because there were problems with consistency. Some of those issues are the same with LVT/SPC/WPC. That shows the importance of what we’re doing here.”

Digital printing in ceramic skyrocketed in 2011. Why? “The first thing is the industry started to recognize the obvious advantages of digital printing, and that it would be the future,” Koopmans noted. “Also at that time, there was the ability to combine décor and texturing [during the printing process], which to that point had been a big challenge in the ceramic industry. Now, they’re not only printing décor but décor and texture.”

Previously, the traditional way to create texture in ceramics was through stamping techniques—which resulted in huge inconsistency and waste, according to Koopmans. “Digital really solved some of those problems. The texture matches the design perfectly. They could create more complex designs with very high precision.”

At the same time, the quality of digitally printed products became better than traditional printing. Consumers could start seeing the difference. “This is exactly where we are today for LVT, SPC and laminates,” Koopmans stated. “We have been talking about digital printing for a very long time, but now all the factors are aligned [to make the technology viable].”

If digital printing/digital texturing takes off for LVT/SPC it could very well be a game changer without much of a price premium if ceramic is used as an example. “In the end, the ceramic product of today is no more expensive than the product of 2010.”

Patent protection

When it comes to IP and innovation, there is always the confusing issue of patents. Unilin has believed in digital printing and texturing for quite some time, which is why it was very early in investing R&D efforts and securing those efforts with IP protection. It had the first patent for this technology, and since then other parties filed additional patents on additional details that fell under Unilin’s. The patent landscape was unclear because you might need a license from several parties. To that end, Unilin has all its ducks in a row. “The last couple of years we worked really hard to make a patent landscape where people can just decide based on the quality of the technology and not have to worry about who has which patents and what patents they could be infringing on because we cleared it with all other parties,” Koopmans said. “Every patent that we know of that is relevant has been grouped together.”

Van der Stockt referred to it as a one-stop shop. “We had a potential customer tell us, ‘I like this technology, I want to invest in it but I’m not going to take any risks and liabilities. If you want to help me, find me a solution.’ And that’s what we’ve done by making an agreement with these other patent holders.”

One of Unilin’s advantages in this regard lies in its reputation. “We have an enormous network of customers,” Koopmans said. “We have great relationships and people trust us. They see us as a beacon of innovation. When we put our seal on something, it says we believe in this technology and gives our customers trust.”

Just as manufacturers license locking system technology, they will be doing the same for digital printing capabilities. “The big difference is with the locking systems, everybody knows where to go, everybody knows the technical details,” Van der Stockt said. “You have the different suppliers [of licenses], you know the advantages and disadvantages on each. I think [with digital printing/texturing], people are not that knowledgeable yet.”

How it works: Customers license the technology from Unilin but order the machines from Barberán. “One doesn’t happen without the other,” Van der Stockt said. “They buy one line for both digital printing and texturing. It’s one, 100-meter line. And licensees have legal certainty that they get access to the latest technology. And we do a lot of promotional support for our licensees as well; they become part of a global network. We are very well connected, not only to all the manufacturers in the world but also to some of the big buyers.”

Endless opportunities

Unilin says digital printing for SPC is truly in its infancy. Only two complete Barberán machines have been built to date (including the DeepBlue texturing component)—one is in China and the other is in the final testing phase at Barberán headquarters in Spain. That one is ticketed for United Surfaces Solutions, the private-label manufacturer in northwest Georgia. The latter is the first domestic manufacturer to incorporate digital printing into its product portfolio. If all goes according to plan, United will have digitally textured products coming off the line by year’s end.

Only two other companies currently offer digital printing/texturing: Chefla, an Italian company that also has a licensing agreement with Unilin; and German company Hymmen, which operates through a partnership with i4F. CFL will be marketing this technology later in the year, as will Engineered Floors.

Needless to say, Van der Stockt said Unilin has built the better mousetrap. “Aside from the realism in visuals, what you also want is scratch resistance,” he explained. “And I hear from the market, from a lot of companies that have tested the different options, that the Barberán combination scores best on those two points. The visuals and the texture are the nicest, they give the best imitation of real hardwood, but also the scratch resistance is outperforming the alternatives on the market due to their technology.”

The next step is finding partners who want to differentiate themselves and are willing to invest in producing the most realistic LVT/SPC/WPC on the market. “I believe people want that texturing,” Van der Stockt said. “Embossed in register has been a game changer in our industry. It needs to feel like a real hardwood.”