Since its inception in 2014, Benchwick—a subsidiary of Northann Corp., a producer and full-range service provider of natural and sustainable materials used for interior finishes—has largely operated behind the scenes. As the parent company of Benchwick, Northann develops and produces high-quality flooring, wall panels and decorative surfaces in the U.S. as well as in Canada and Europe. The company is one of the world’s leading providers of 3D printing for a variety of home improvement industries.

Since its inception in 2014, Benchwick—a subsidiary of Northann Corp., a producer and full-range service provider of natural and sustainable materials used for interior finishes—has largely operated behind the scenes. As the parent company of Benchwick, Northann develops and produces high-quality flooring, wall panels and decorative surfaces in the U.S. as well as in Canada and Europe. The company is one of the world’s leading providers of 3D printing for a variety of home improvement industries.

As one of the fastest growing flooring producers, Benchwick earned a solid reputation by supplying many of the industry’s well-known SPC, WPC and LVT brands on a strictly private-label basis. Now, that’s changing. As the red-hot resilient category continues to grow by leaps and bounds—and as technological innovations in everything from digital printing to surface texturing advance apace—Benchwick is seizing a golden opportunity to make a name for itself by moving from the background to the forefront in flooring manufacturing technologies. That means not only supplying the flooring that has become so popular in the U.S. market today, but also leveraging manufacturing innovation and visual/surface texturing technology to drive the entire industry forward.

“We used to be solely an OEM factory; now we are switching from OEM producer to innovator and promoting our own brand,” said Ken Li, president, Benchwick. “Our company is pretty young; we only have an 8-year history. But in the past few years we have developed some very unique innovations.”

One of those innovations is Blue 11, a new rigid core line that features a core made with 80% recycled plastic recovered from oceans and waterways. As opposed to SPC floors that primarily utilize materials derived from oil or virgin PVC, Blue 11 offers a more sustainable and feasible alternative to current manufacturing methods that are dependent on petroleum. “That’s thousands of tons of plastic recovered from the ocean,” Li explained. “Most of the core materials used in existing rigid core products are more susceptible to oil prices; we don’t have to worry about that.”

Beyond its environmental appeal, the core material utilized in Blue 11 touts improved stability and impact/dent resistance over previous SPC iterations. In fact, Benchwick considers it a new kind of rigid flooring. “Not only is the core more sustainable, but it is more stable due,” Li stated. “It’s a 4mm product with the performance similar to an 8mm SPC. It’s also much lighter.”

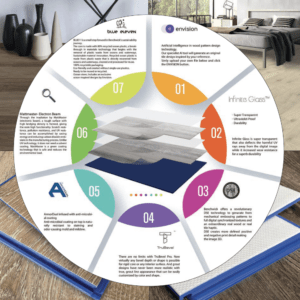

The attributes of Blue 11 don’t end there. The product boasts a host of other top-to-bottom innovations thanks to Benchwick’s signature 3D printing ecosystem (see diagram above). Utilizing sophisticated, patent-pending technology, Benchwick has the capability to digitally print images directly to the core material. “We don’t use any film or wear layer on the top of the surface,” Li noted.

Other key attributes of Benchwick’s 3D printing ecosystem include:

- Envision—An AI-inspired image rendering tool that allows for more customized replications of tile, stone and hardwood visuals.

- Infinite Glass—An ultra-transparent yet highly durable overlay that protects the underlying design image from damaging UV rays.

- DSE—Proprietary digital embossing technology that matches the surface texture with the visual characteristics of the underlying image.

- TruBevel Pro—Enables more life-like bevels on boards featuring wood designs as well as realistic grout lines on tile stone patterns.

- ArmorDual—Special antimicrobial coating that resists stains and fights odor-causing mold and mildew.

- Mattmaster—Electron beam technology creates a tough, scratch-resistant surface while still delivering a more natural, low-sheen appearance.

All these attributes, according to Li, give Benchwick a competitive advantage. “We spent the last four years creating the signature ecosystem; we totally built them from ground zero,” he told Floor Covering News. “We develop all the innovations in house—we don’t outsource anything to outside companies. And we have intellectual property on the technologies we use to create the product.”

It’s also worth noting that Benchwick owns the factory where these technologies are employed. It represents a departure from the norm whereby so many companies rely solely on third-party suppliers or importers. By owning and operating the facilities, Benchwick has a vested interest in the manufacturing process and, ultimately, the quality of the products coming out of the plant. This translates into higher levels of confidence among its customers. “We have passed hundreds of quality and environmental tests, not only in Asia but also California and Dalton,” Li stated.

Benefits for end users

Benchwick’s numerous capabilities on the manufacturing/R&D fronts extend to its distributor and retail customers. First and foremost, Benchwick is in the enviable position to offer its wholesaler partners exclusive products and designs tailored to their respective markets. While the company intends to put more emphasis on its own brand, it left the door open to do some cross-branding with select partners. “We could have some exclusive distributors in the market where we will guarantee our customers are protected in those areas,” he said. “We can also offer customers unique patterns, designs and colors in certain markets.”

Second, due to alternative production methods combined with a more economical manufacturing cost structure, the company is able to fill orders more quickly. This is especially important in today’s environment where shipping is still a concern for many importers.

“Our supply chain is different from traditional WPC/SPC manufacturers, so we can provide a faster turnaround,” Li noted. “When you use digital printing direct to core you don’t have to worry about films or wear layers or inks.”

Third, due to its scale, Benchwick can supply high volumes for bigger orders or larger customers. “We have the capacity to ship 300 containers—or 8 million square feet—per month,” Li said. “Most of our customers receive the containers direct.”

A large Midwest-based flooring distributor, speaking on the condition of anonymity due to contractual obligations, attested to Benchwick’s prowess and capabilities. “Benchwick has developed several innovating technologies that separate them from much of what’s on the market today,” the executive said.

Long-term plans

With nearly 90% of the company’s revenue generated by U.S. customers, Benchwick is looking into the possibility of establishing a manufacturing base in America in the near future. This would help improve service levels to a customer base that is only expected to grow larger in the years to come.

“We expect to bring our digital printing ecosystem to the U.S.,” Li noted. “At the same time, we will keep our facility in Asia for the purposes of research and development. In the end, we are trying to create more imagination and sustainable innovation for the industry.”