Hannover, Germany—i4F, a group of companies providing patents and technologies to the flooring industry, has entered into a strategic patent partnership with HMTX Industries—a global flooring company and leading innovator in flooring technologies. As a result of the agreement, i4F has secured exclusive rights to license HMTX’s SRP rigid core TPU flooring technology to third-party decorative panel manufacturers. The rights cover the technology and know-how to enable manufacturers to produce, offer and sell SRP flooring products. i4F said its ultimate goal is to position SRP products as the market standard for decorative floor covering panels.

Hannover, Germany—i4F, a group of companies providing patents and technologies to the flooring industry, has entered into a strategic patent partnership with HMTX Industries—a global flooring company and leading innovator in flooring technologies. As a result of the agreement, i4F has secured exclusive rights to license HMTX’s SRP rigid core TPU flooring technology to third-party decorative panel manufacturers. The rights cover the technology and know-how to enable manufacturers to produce, offer and sell SRP flooring products. i4F said its ultimate goal is to position SRP products as the market standard for decorative floor covering panels.

SRP Rigid Core TPU flooring is a patent-pending recyclable technology developed as an environmentally conscious solution to alleviate the challenge of single-use plastics developed by HMTX Industries, in partnership with Huntsman.

“We are more than proud to partner with HMTX on this ground-breaking technology,” said John Rietveldt, i4F CEO. “Together, we are redefining the standards for fully sustainable flooring. SRP rigid core TPU flooring is a spectacular example of flooring circularity in action as it delivers a renewable technology that relives again and again. This means that flooring may never need to go to a landfill. Instead, it finds new life and evolves for a new generation.”

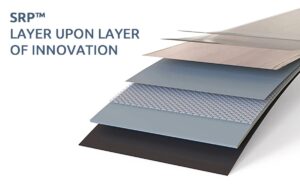

Two plastic bottles (PET) are upcycled into each square foot of SRP flooring, with a cross-linked polyurethane top layer, thermoplastic polyurethane (TPU) core layer and a cross-linked foam back layer. Ultimately, the product will be transformed to an engineered thermoplastic polyurethane (TPU), which will be the foundation of a single polymer construction. In what i4F bills as a first for the flooring industry, and after a lifetime of use and reuse, SRP TPU rigid core flooring is designed to be recovered and remade into new SRP TPU flooring with the exact same characteristics: forged from the ground up for a circular economy.

SRP flooring products are initially made with more than 20 PET water bottles per square meter of flooring, helping to reduce the amount of waste plastics in the environment. The planks and tiles are engineered to be recycled into new SRP flooring when they reach their end of life while maintaining product performance and quality.

SRP rigid core TPU flooring is on show at i4F’s booth at Domotex Hannover. The technology has also been nominated for a Green Collection in the eco-friendly products category.