December 10/17, 2018: Volume 34, Issue 14

By Reginald Tucker

Wood flooring manufacturers are pushing the boundaries of style and design by applying various surface finishing/coloring techniques to give consumers a greater range of options.

Wood flooring manufacturers are pushing the boundaries of style and design by applying various surface finishing/coloring techniques to give consumers a greater range of options.

Case in point is the new Floorté Hardwood line from Shaw Floors. Named after one of the company’s most popular resilient flooring collections, Floorté Hardwood utilizes special surface technologies to create unique products for retailers to sell. With a waterproof SPC core and a hardwood veneer, Floorté Hardwood offers both style and durability.

“To accentuate the beauty of its hardwood veneers, we employed advanced finishing techniques such as reactive staining, wire brushing, balayage highlighting, white and black accent graining as well as band saw marking, to name a few,” Drew Hash, vice president, hard surface portfolio, explained. “These techniques, which are displayed on the brand new Floorté Hardwood’s Exquisite collection, allow us to manufacture products that suit any style preference—from urban or rustic to traditional and modern.”

Innovative surface finishing techniques are also featured on Shaw’s new Repel-branded hardwood offering. Each style in the collection, which plays on the water-resistant capabilities of the laminate line of the same name, features a variety of surfacing techniques to enhance the natural character of the wood.

Mohawk is also utilizing a variety of scraping techniques to render different looks for the consumer. Its TecWood line, for instance, offers various options based on different levels of distressing. In illustration: Castlebriar offers six sophisticated styles of wire-brushed oak enhanced with the company’s “Natural Alchemy” staining process, while Hartwick offers five unique rustic oak colors with smooth surface. Then, there’s Hideaway Ridge, which features five softly scraped oak styles with vibrant color variations, followed by Sheridan, which comprises six unique fashion-forward oak varieties with wire-brushed surface. Lastly, Windrose offers five genuine dry-sawn oak options that reflect the natural beauty of hardwood.

Additionally, TecWood’s thicker, premium veneer provides greater durability with additional benefits that keep floors looking newer longer and performing better over the long term. “Innovation is at the heart of every TecWood product, and our enhanced engineered construction gives our new collections greater stability, density and weight,” said Angela Duke, director of brand marketing.

Other major manufacturers are employing surface finishing techniques in novel ways. Provenza, long known for its artistic approach in coloring, treating and applying different surface textures to its wood products, offers retailers an ever-growing catalog of eye-catching products enhanced by manual artisan techniques.

Among the most popular lines: Dutch Masters collection, a wide-plank, European oak prefinished engineered hardwood offering with a light to heavy wire-brushed surface and multi-stain process; the award-winning Colour Nation Lighthouse Cove collection, also a wide-plank, European oak prefinished engineered hardwood line featuring a multi-color, multi-layered paint technique; and the Old World hardwood collection, which boasts a wire-brushed, hand-distressed treatment combined with an innovative smoking and carbonizing technique.

Provenza takes it a step further by applying a “fuming” technique to add greater depth and dimension. “We combine that with staining and oil looks to create a UV oil, which provides a harder, smoother finish with less maintenance,” said Ron Sadri, principal owner. “The technology has evolved to the point where we went from hard wax finishes to polyurethane combined with reactive stains.”

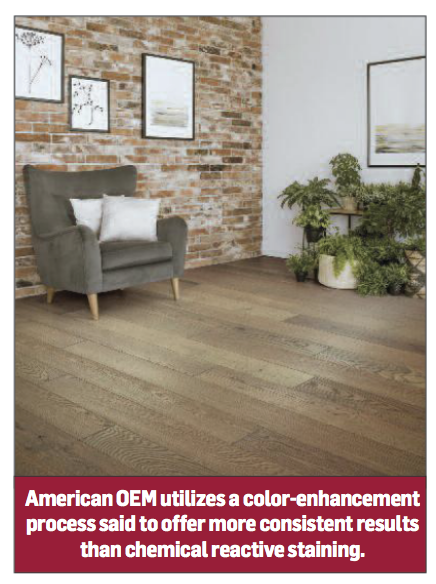

Experimentation with innovative staining techniques has also produced positive results for companies like American OEM. Take its Controlled Chaos and Dynamic Earth lines, for example. The technology Hearthwood employs on these offerings is very similar to chemical reactive staining but it produces more consistent results, according to Allie Finkell, executive vice president. “Some of the chemical reactive staining processes are really hard to control, making it difficult to be consistent across production over time and from run to run. But we’ve been able to recreate the highlights of those chemicals utilizing a regular water-based UV-cured stain, which is done in our Tennessee plant with low-emitting finishes.”

Controlled Chaos features a light, wire-brushed finish on white oak for a more contemporary look in a 7-inch-wide x 8-foot-long format in colors ranging from, in Finkell’s words, “shocking to subtle.” Meanwhile, Dynamic Earth, which is also in a sliced white oak product, has more of a reclaimed, scraped texture. “Our handscraping technique is not the old, machine-scraped process that’s so common in the industry,” Finkell told FCNews. “Our process delivers more of that reclaimed barnwood look. This way the customer gets a modern format in long lengths and wide widths, but she can still pick a timeless color that she’s going to love for years.”