*******

This is a partnered post with LENOX® Tools.

In Part 1 of this article, we looked at how from humble beginnings in hacksaw blades LENOX Tools has grown to become a leader in power tool accessories. LENOX has been at it, after all, for more than 100 years. We looked at how a continued dedication to the science of cutting has yielded advancements in their newest reciprocating saw blades.

Continuing here, I’ll take a look at how those same engineering insights also impact LENOX’s newest generation of hole saws. We’ll see how improvements in hole saw design is born out of the century-long study of saw blades.

In Part 1, I looked at when and how we use reciprocating saws. Ultimately, I also discussed what we should and do look for in our reciprocating saw blades. Here, however, we’re talking hole saws, starting again with the tasks we must commonly perform.

Talking the Tasks that Tradesmen Perform

Plumbers, Electricians, and HVAC technicians frequently reach for bi-metal hole saws when running their respective lines through the interior of a home. Finish carpenters and remodelers, too, grab their hole saws when installing old-work recessed lighting, with setting vanities or cabinets, and with making bores, for example, in door slabs. Whoever you are, the right hole saw is essential when you need a clean exterior penetration.

Now, there is one sometimes frustrating part of using a hole saw, and especially if you are working in a production setting. Yep, you guessed it – clearing the waste, aka plug, from your saw between cuts.

We’ve all been there, I think … at a dead stop, stuck freeing a tightly wedged plug after a perfectly placed cut. That part sometimes seems to take as long as pulling out the drill and drilling the hole in the first place. Nuts!

LENOX Bi-Metal SPEED SLOT® Hole Saw with T3 TechnologyTM

I mean – have you ever had a cut so unforgivingly wedged into a hole saw that you had to completely disassemble it from the mandrel to get the little bugger out? OR have you ever stowed your hole saw away only to have that same pesky plug awaiting you the next time you pull it out?

The SPEED SLOT

Fine Homebuilding’s Justin Fink claimed that LENOX Tools solved these problems. Demoing shortly after its release, he points to a small, but revolutionary tweak in their saws’ design. The Speed Slot – a staircase / stepped slot in the side of the saw’s body that provides three separate leverage points for quick plug ejection.

Since LENOX introduced the BI-METAL SPEED SLOT© HOLE SAW, it has appeared on LENOXTM hole saws since 2011. And it has been imitated over and over. (And you know what they say about imitation.) Honestly, though, and if you’ve used any of the imitators, you know, the slots on other leading brands are sometimes overly-complex and, I’m sorry but, perhaps not as easy to use as this original.

Taller Bodied

In fact, I’d say LENOX’s design towers over the competition. No, literally. LENOX® also gives their hole saws a body that is slightly taller than most. And why, JB, is that important?

Well, by making their hole saws a fraction of an inch taller, LENOX® leaves you more area, a bigger gap below the plug to slide in, say, a round- or hex-shaft, slotted screwdriver. This is especially important when working with thicker 2x material. I mean – how good is a slot in the side of a hole saw if you can’t even get removal started?

Bottom Line: In my experience and, well, others, the angled stair stepping of the BI-METAL SPEED SLOT© HOLE SAW simply facilitates the fastest possible plug removal. And faster, easier removal of plugs means, as Pro Tool Reviews puts it – higher productivity and less down time on the job site.

So What Exactly is T3 Technology?

Specialty one-tooth, recessed light, Grit and Diamond options are available. But the focus here, the bi-metal saws have high-speed carbide teeth welded to a high-strength carbon steel base.

Note: I discuss the value of carbide steel in Part 1, here.

New LENOX Bi-Metal Hole Saws feature T3 Technology. What, JB, does that mean?

- These saws still have that best-in-class plug removal system – the BI-METAL SPEED SLOT© HOLE SAW.

- They have Larger Teeth for optimal cutting.

- They have Thicker Walls for increasing strength and durability, especially when cutting metal.

These engineering advancements yield Faster Cutting, Longer Life, plus Superior Durability. In fact, LENOX says they’ll last 50% longer and have double the cutting power over previous iterations.

Engineering at Work :: Tooth Design

The team at LENOX has continued to refine tooth design, giving these hole saws larger, sharper teeth. They’re said to remove more wood for fast cutting, longer. The latest version of these saws are also 10x thicker than the earlier models. The thicker walls increase kerf size, but improves the long-term durability of saws, making for more precise and cleaner cuts. (Cleaner cuts, also, ironically, mean plugs are ultimately easier to remove.)

Engineering at Work :: Paint-Free Interior Walls

Distinct also to LENOX hole saws, you’ll notice, interior walls are free of paint. And think about this – a painted surface when super-heated can create a molecular residue (or something) that will stick to the other materials, like sawdust. Here, waste wood doesn’t have a chance to bond to a gummy paint residue, again potentially making plugs harder to remove.

Engineering at Work :: More Efficient Metal Cutting

While I personally don’t do much hole cutting in metal, HVAC guys and other home improvement pros will see added value in the newest improvements. The increased wall thickness minimizes tooth loss, while optimizing for these types of cuts.

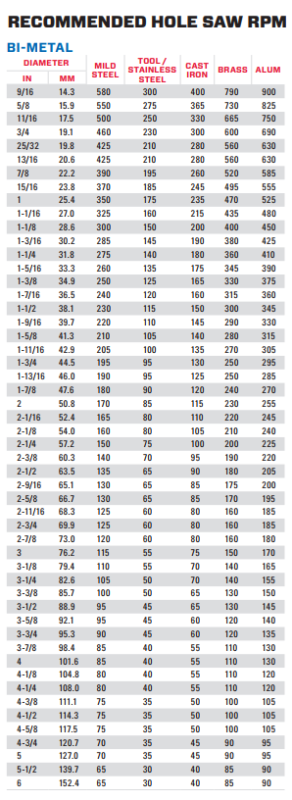

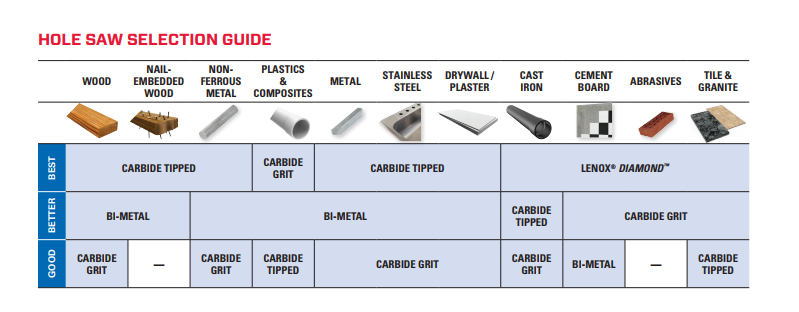

To learn more about T3 Technology, see information about LENOX Bi-Metal Hole Saws here. Probably my fav though – the tech spec, which includes information like a Selection Guide (pictured below), Recommended RPM by various tasks (pictured above), and part numbers for various kits and accessories.

LENOX Bi-Metal SPEED SLOT Hole Saws with T3 Technology come in 52 sizes – from 9/16” to 6” and are capable of addressing anything from pressure treated wood to cast iron. Task- / trade-specific, as well as general purpose, kits, like LENOX Contractor’s Carbide Tipped Hole Saw Kit, are available. The entire line of bi-metal hole saws is compatible with any standard hole saw mandrel.

LENOX :: Saving Time & Making Money

The thicker blade wall on their newest product offerings increase durability. From this, we see less tooth loss. This makes for more accurate and efficient cutting, while simultaneously minimizing the need to purchase replacements.

The longer lifespan of these hole saws, doesn’t just mean you’ll get your money’s worth, it means more cuts made when you need to make them. They’re engineered to perform fast for people who do not have time to waste on the job.

********

And now, back to the question I asked (well, myself) at the top of this article. How much thought do I really give to the power tool accessories I reach for? Answer – some. I (like you) put a lot of thought into my work, and it seems – I also appreciate tools that are engineered with an equal amount of thought and care.

Thanks for reading.~jb

Normally i don’t find blogs or articles which also cover the technical parts of construction. This was one heck of an article. Very informative and good quality. Today this is what most of the construction and remodeling companies are using like Bsd constructions situated in LA.