The construction industry as a sink for carbon dioxide? This is being worked on by researchers at Empa’s Concrete & Asphalt lab. They are investigating the possibility of CO2-neutral or even CO2-negative concrete by blending biochar into it. They turn the biochar into pellets for maximum use, which they then utilize in place of traditional aggregates.

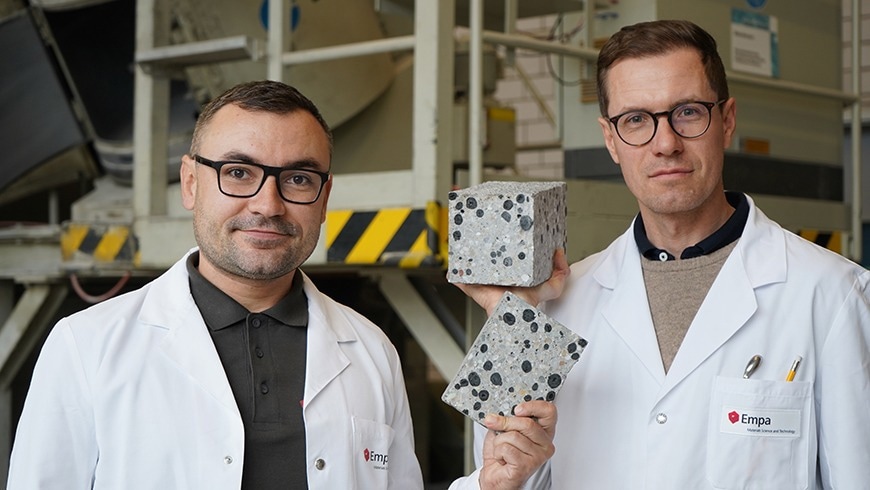

Concrete without emissions: Empa researchers Mateusz Wyrzykowski (right) and Nikolajs Toropovs are replacing conventional aggregates with pellets made from biochar, thus exploring the potential of CO2-neutral or even negative concrete. Image Credit: Empa

Strategies and procedures with a negative CO2 balance are required if Switzerland is to become climate-neutral by 2050. To ensure that net zero is ultimately achieved, these so-called negative emission technologies (NET) are designed to offset the remaining “hard-to-avoid” emissions in 2050.

The construction industry is particularly responsible because it is one of the major emitters. The production of cement is responsible for around 8% of greenhouse gas emissions worldwide.

Simultaneously, there are attempts underway to utilize the construction industry, with its large resource consumption, as a potential carbon sink. If “building with CO2” is started—that is, utilizing carbon to create building materials and eventually extracting it from the atmosphere—the seemingly paradoxical idea will come to pass.

Much research is required for such dreams to come true, such as that which is being done in Empa’s Concrete & Asphalt facility right now. A group under the direction of Pietro Lura is creating a method for incorporating biochar into concrete.

Difficulties Due to Porosity

Biochar is mostly made of pure carbon, which is the carbon that plants take up from the environment in the form of CO2 as they develop. It is created via the pyrolytic carbonization of biomass in the absence of oxygen. Burning plants releases CO2, but over time, the gas stays trapped in the biochar. The first concrete goods that use biochar are already available for purchase.

Unfortunately, untreated biochar is frequently added to concrete, which can cause problems.

Biochar is very porous and therefore not only absorbs a lot of water, but also expensive admixtures used in concrete production. Moreover, it is difficult to handle and not completely harmless either.

Mateusz Wyrzykowski, Researcher, Swiss Federal Laboratories for Materials Science and Technology (Empa)

In addition to being hazardous to the respiratory system, fine coal dust explodes occasionally.

For these reasons, the researchers suggest turning biochar into pellets in a recently published work in the Journal of Cleaner Production.

“Such lightweight aggregates already exist from other materials such as expanded clay or fly ash. The knowhow in handling these materials is available in industry, and this increases the chances that the concept will be put into practice,” Wyrzykowski added.

Net Zero at 20 Percent Share

The researchers blended biochar, water, and cement in a concrete mixer with a revolving pan to create the pellets. The spinning produced tiny pellets that ranged in diameter from 4 to 32 millimeters. The typical concrete of strength classes C20/25 to C30/37, which are currently the most used in civil engineering, was then created using these pellets.

Wyrzykowski further stated, “With a proportion of 20 percent by volume of carbon pellets in the concrete, we achieve net zero emissions.”

In other words, the quantity of carbon stored balances out all the emissions generated during the manufacture of the concrete and the pellets. The negative emission potential is most noticeable for lightweight concrete (density about 1,800 kg/m3), even if the limit has probably not yet been achieved for regular concrete (density between 2,000 and 2,600 kg/m3) with 20 % by volume: Total negative emissions are minus 290 kg CO2/m3 when carbon pellets are added to the concrete at a volumetric ratio of 45%. Conventional concrete, on the other hand, releases around 200 kg CO2/m3.

Carbon from the Atmosphere

According to Pietro Lura, the leader of the lab, research in his lab is essential to meeting climate objectives. Although biochar has been used as a model material in recent studies, he does not believe that biochar is the most significant source of carbon.

Instead, he highlights the overarching idea of “Mining the Atmosphere,” which is being investigated by several Empa laboratories. This involves producing synthetic methane in sunny parts of the planet by combining solar energy, water, and CO2 from the atmosphere, then pyrolyzing the resulting gas.

This yields hydrogen, which can be used as an energy carrier in industry or mobility, and solid carbon, which we can process into pellets – like biochar – and incorporate into concrete.

Pietro Lura, Laboratory Head, Swiss Federal Laboratories for Materials Science and Technology (Empa)

Journal Reference

Wyrzykowski, M., et. al. (2023) Cold-bonded biochar-rich lightweight aggregates for net-zero concrete. Journal of Cleaner Production. doi:10.1016/j.jclepro.2023.140008