The current building industry faces many issues. Natural sand is rapidly becoming a rare resource; humanity may run out of it by 2050. Carbon dioxide emissions are growing year after year, particularly from the production of cement or fired clay bricks. Construction and demolition (C&D) waste is increasing - over 150 million tons are created yearly in India, and the recycling rate is just about 1%.

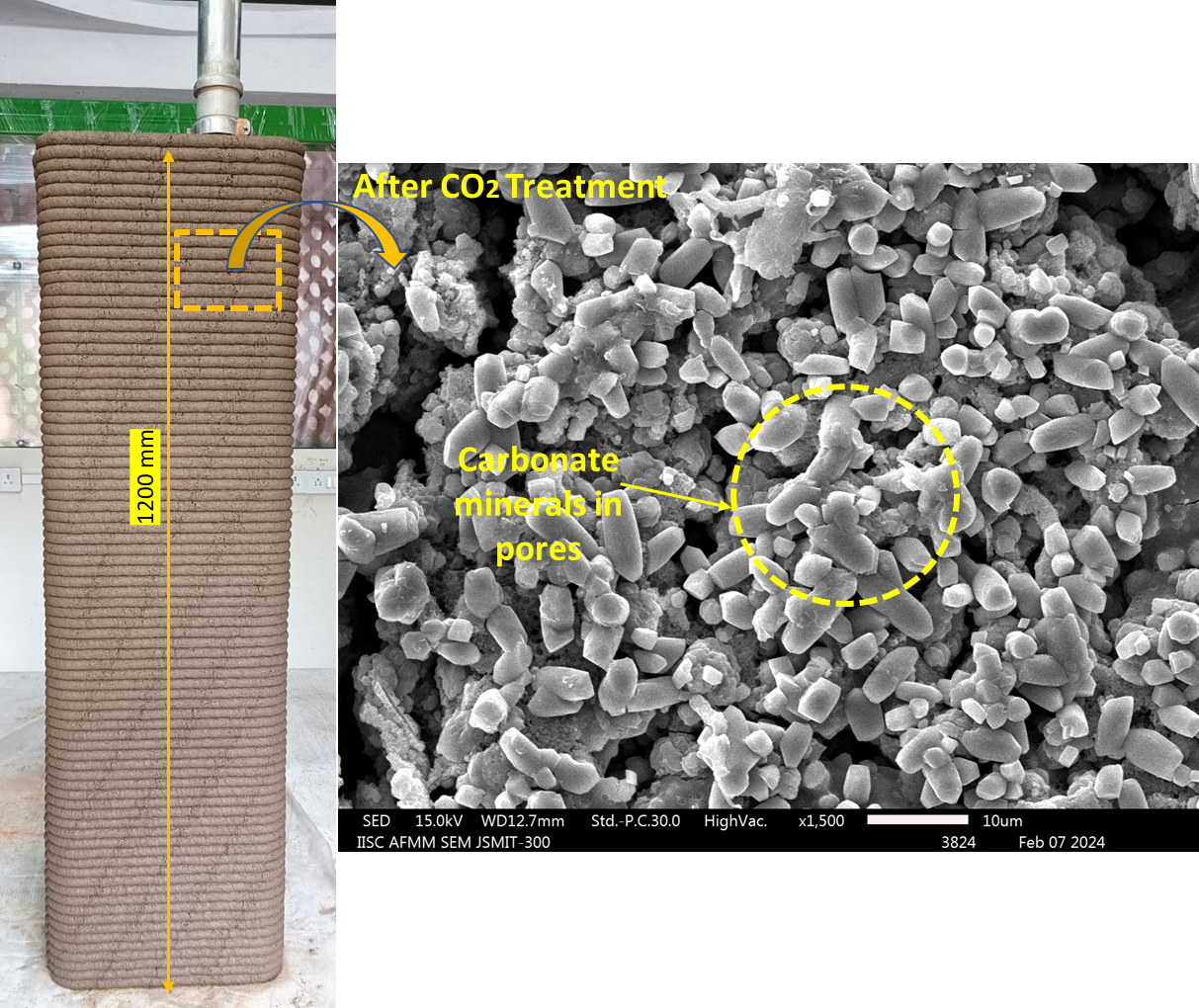

Formation of carbonate minerals in the pores and bulk matrix of the developed 3D printable material during carbon sequestration. The crystals are 3-5 micrometers in size and thus densify the material matrix. Image Credit: The MatERIAL group, CST, IISc

Formation of carbonate minerals in the pores and bulk matrix of the developed 3D printable material during carbon sequestration. The crystals are 3-5 micrometers in size and thus densify the material matrix. Image Credit: The MatERIAL group, CST, IISc

To address these difficulties, researchers at the Indian Institute of Science's Centre for Sustainable Technologies (CST) are looking at ways to store carbon dioxide from industrial flue gas in excavated soil and C&D waste.

These materials can then be utilized to partially replace natural sand. This would not only lessen the environmental effect of construction materials but also confer qualities that would improve their suitability for construction.

CO2 utilization and sequestration can be a scalable and feasible technology for manufacturing low-carbon prefabricated building products while being aligned with the nation’s decarbonization targets.

Souradeep Gupta, Assistant Professor, Centre for Sustainable Technologies, Indian Institute of Science

Gupta’s team demonstrated that substituting natural sand with carbon dioxide-treated C&D waste in mortar and curing it in a controlled, CO2-rich atmosphere could speed up the development of the material's technical characteristics and increase compressive strength by 20–22%. His study also investigated the effects of injecting carbon dioxide gas into clayey soil, often dug from construction sites.

This resulted in greater clay stabilization by cement and lime and a reduction in clay surface area, pore volume, and lime reactivity in soil, increasing the material's bulk engineering performance.

In a recent study, Gupta’s team investigated what occurs when carbon dioxide is sequestered in excavated soil to create cement-lime-soil composites, which are subsequently utilized to replace up to 25% and 50% of fine aggregates by mass in mortar.

When you sequester carbon dioxide in cement-soil materials, tiny crystals of calcium carbonates are formed, which reduce the fraction of medium capillary pores, densify the interfacial zones and thus improve the compressive strength.

Ashutosh Dwivedi, Study First Author and PhD Student, Centre for Sustainable Technologies, Indian Institute of Science

Researchers discovered that exposing the cement-lime-soil block to carbon dioxide boosted its early-age strength by around 30%. According to Gupta, carbon dioxide exposure after preparation reduces their curing time, which is the time it takes for them to solidify before they can be employed in construction.

The team has also created 3D-printable materials from excavated soil stabilized with a mix of binders such as Portland cement, blast furnace slag (a granular calcium-silicate byproduct), and fly ash. They discovered that the non-expansive clay in the excavated soil functions as an effective thickening agent (rheological modifier), giving the material improved extrusion and buildability compared to traditional cement-sand mortars.

According to their findings, using these materials might lower the quantity of cement and natural sand required in mortar by 30% and 50%, respectively.

Moving further, the team intends to investigate the influence of industrial and simulated flue gas—a mixture of gases such as carbon dioxide, sulfur dioxide, nitrogen oxide, and others—on the micro and macro characteristics of these newly created materials. This would allow them to determine if gases other than carbon dioxide emitted by companies impact the materials’ carbon-capturing capacity and technical features.

The team is in discussions with a few significant construction firms to implement these discoveries in their manufacturing facilities. In addition, Gupta is a member of a national committee that is now updating the requirements for recycled and natural aggregates in cement-based construction materials.

Gupta concluded, “The climate change impacts of construction materials, exacerbated by increasing CO2 emissions and sand scarcity, are increasing every year. Finding alternatives to natural sand is the need of the hour.”

The Department of Science and Technology (DST) under the Trans-National Project on Accelerating Carbon capture, utilization, and storage Technologies (ACT) supported the study.

Journal References:

Dwivedi, A., et. al. (2024) Carbon dioxide sequestration in mortars with excavated soil: Engineering performances and environmental benefits. Science of The Total Environment. doi:10.1016/j.scitotenv.2024.171654

Soda, P.R., et. al. (2023) Development of 3D printable stabilized earth-based construction materials using excavated soil: Evaluation of fresh and hardened properties. Science of The Total Environment. doi:10.1016/j.scitotenv.2024.171654

Dwivedi, A., et. al. (2023) Influence of carbon sequestration in natural clay on engineering properties of cement-lime stabilized soil mortars. Developments in the Built Environment. doi:10.1016/j.dibe.2023.100270

Sahoo, P., et. al. (2023) Sequestration and utilization of carbon dioxide to improve engineering properties of cement-based construction materials with recycled brick powder: a pathway for cleaner construction. Construction and Building Materials. doi:10.1016/j.conbuildmat.2023.132268